Premium Crusher Blow Bars

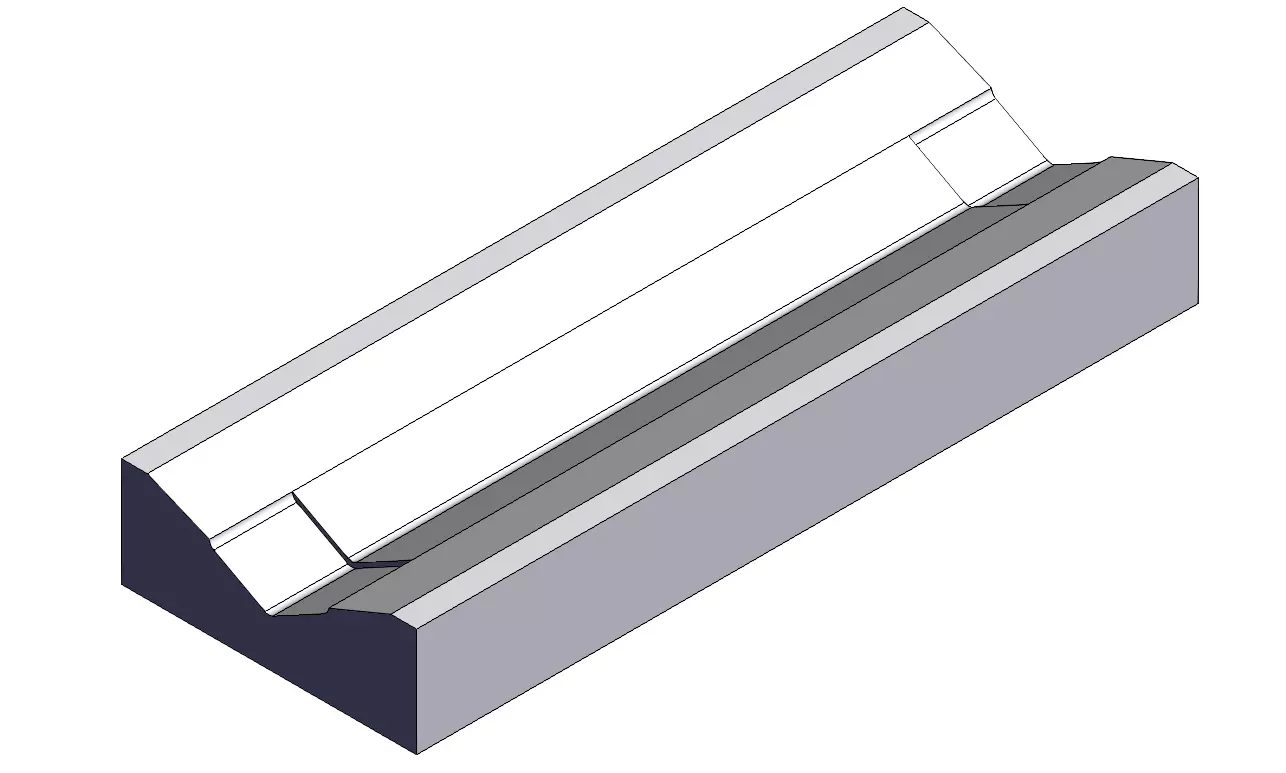

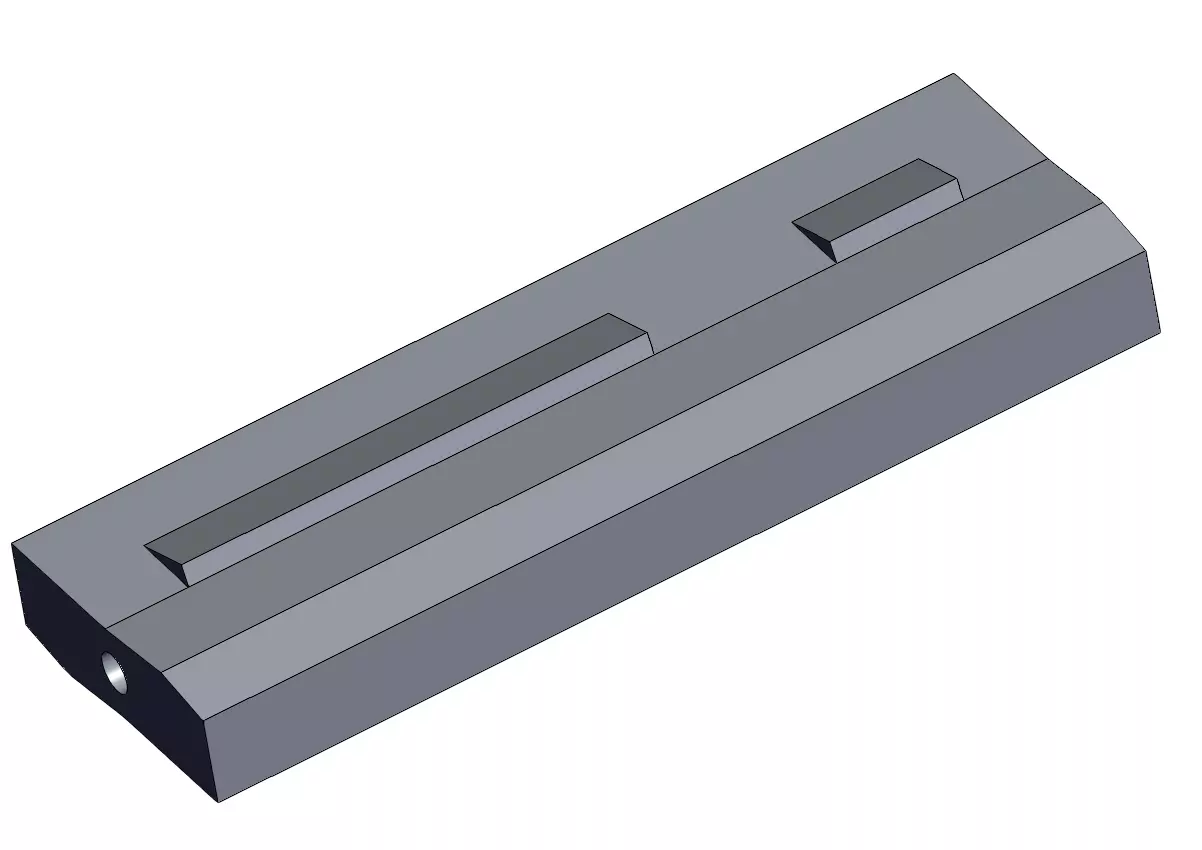

Crusher blow bars are thick slabs of metal, typically some mixture of chrome, that are cast for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc. Often in sets of 3 or 4, blow bars are inserted into an impact crusher’s rotor where they are able to strike material needing to be processed. As an important component of horizontal shaft impact crushers, blow bars come into direct contact with material and provide a powerful impact force. HSI crushers and their blow bars are designed to fracture material quickly, resulting in high production rates and reduced costs per ton when compared to other types of crushers.

- Common Aliases: Crusher blow bars, break plates, impact blow bars, impact crusher hammer

- Main Material: Mn14, Mn18, Mn22, Manganese steel with TIC inserts, Martensitic steel, Metal matrix with ceramic composites

- Cast Methods: Lost foam casting, Sand casting, V-method casting

Crusher Blow Bars By Hunan JY Casting®

When it comes to crusher blow bars, Hunan JY Casting manufactures high-quality replacement blow bars for popular brands. No matter which brand crusher blow bars you want; No matter which material blow bars you need; No matter which sharp of blow bars you inquiry; JY casting is your first choice! In some cases, our crusher blow bars’ lifetime 100% matches the original wear parts.

Hunan JY Casting’s Cone Crusher Liners Suit:

Crusher Blow Bars FAQ

Which Material Hunan JY Casting manufactures for crusher blow bars?

Manganese Steel Blow Bars

Hunan JY Casting manganese steel blow bars are made in our own materials that have been developed from the original Hadfield’s manganese steel specification. Our variations can provide unequaled toughness with excellent resistance to abrasion, which improves as the steel work hardens in operation. Available in M14, M18, and special order M21 manganese steel.

The wear resistance of manganese steel with austenitic structure is attributable to the phenomenon of work hardening. The impact and pressure load result in a hardening of the austenitic structure on the surface. The initial hardness of manganese steel is approx. 20 HRC. The impact strength is approx. 250J/cm².

After the work hardening, the initial hardness can thereby reach up to approx. 50 HRC. The deeper-set, not yet hardened layers thereby provide for the great toughness of this steel. The depth and hardness of the work-hardened surfaces depend on the application and type of manganese steel.

This material is widely used in crusher jaws, crusher cones, and crusher shells, not common in impact crushers. However, when crushing less abrasive and large feed material(such as limestone), the manganese blow bars are the best choice.

Martensitic Steel Blow Bars

Martensite is a completely carbon-saturated type of iron that is made by quick cooling-off. It is only in the subsequent heat treatment that carbon is removed from the martensite, which improves the strength and wear properties. The hardness of this steel ranges between 44 to 57 HRC and the impact strength between 100 and 300 J/cm². Thus, with regard to hardness and toughness, martensitic steels lie between manganese steel and chrome steel. They are used if the impact load is too little to harden the manganese steel, and/ or good wear resistance is required along with good impact stress resistance.

Martensitic steel lies between manganese and chrome steel. It’s used if the impact load is too little to harden the manganese steel, and good wear resistance is required along with good impact stress resistance.

Chrome Steel Blow Bars

With chrome steel, the carbon is chemically bonded in the form of chromium carbide. The wear resistance of chrome steel is based on these hard carbides of the hard matrix, whereby the movement is hindered by offsets, which provides for a high degree of strength but at the same timeless toughness. To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm². To prevent the breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.

Chrome steel is the common material in casting HSI blow bars because it has a very good hardness. Regularly, chrome steel typically has a hardness of 60 to 65 HRC. And if we increase the elements “Mo” content, it also can get very toughness and wearable, not easy break.

Metal Matrix With Ceramic Composites Blow Bars

Metal Matrix Composites, combine the high resistance of the metal matrix with extremely hard ceramics. Porous preforms made of ceramic particles are produced in the process. The metallic molten mass penetrates into the porous ceramic network. The experience and knowledge are particular to the casting process in which two different materials – steel with a thickness of 7.85 g/cm³ and ceramic with a thickness of 1-3 g/cm³ – are combined and there is a thorough infiltration.

This combination makes the blow bars especially wear-resistance but at the same time very impact-resistant. WIth blow bars made of composites from the field of ceramics, a service life that is three to five times as long as that of martensitic steel can be achieved.

How and When to Change Crusher Blow Bars?

If your crusher is operating at capacity, the blow bar may need to be replaced after a certain amount of time. This is due to the fact that the bar is a vital component of the crushing machine. High-chrome bars can last for many years without replacement if they are properly maintained. However, if you are working on a smaller project, a change is more frequent than a rebuild.

Factors That Affect How Long Crusher Blow Bars Span Life

One of the biggest factors in determining the life of a blow bar is the amount of wear that the piece experiences. In many cases, the amount of wear is a function of material type, rotor size, and desired reduction ratios. The resulting blow bar wear, combined with excessive wear, can significantly reduce the productivity of an impact crusher. In order to extend the life of the impact crusher blow bar, it is best to flip the bar regularly.

Choosing the Best Material for Crusher Blow Bars

Depending on your application, the material of the crusher blow bars will be affected by the type of feed materials. For concrete, aggregate, and demolition applications, the low chrome bar is most suitable. These bars can handle heavy and large feed materials but are not suited to coarse-grained or highly abrasive materials. High-chrome bars, on the other hand, can be used for a variety of applications.

What is the cast method in your foundry?

We have two process lines: Wood pattern sand casting line and Lose foam casting line.